- CONTACT US

- MOWERS

- VEHICLES

- APPLICATION

- Golf

- AERATORS

- VEHICLES

Training and Machinery Maintenance

CONTENTS

FEATURED STORIES

Reesink Turfcare

Reading time: 10 minutes

Inside Training and Machinery Maintenance

In our last article we spoke about the importance of training and how those in the industry have benefitted from it. Here we discuss how training benefits machinery maintenance, particularly in the winter.

At this time of year, the winter season brings with it a reminder to ensure our turf machinery is up to scratch, ready for the year ahead and able to deal with the challenges colder weather brings.

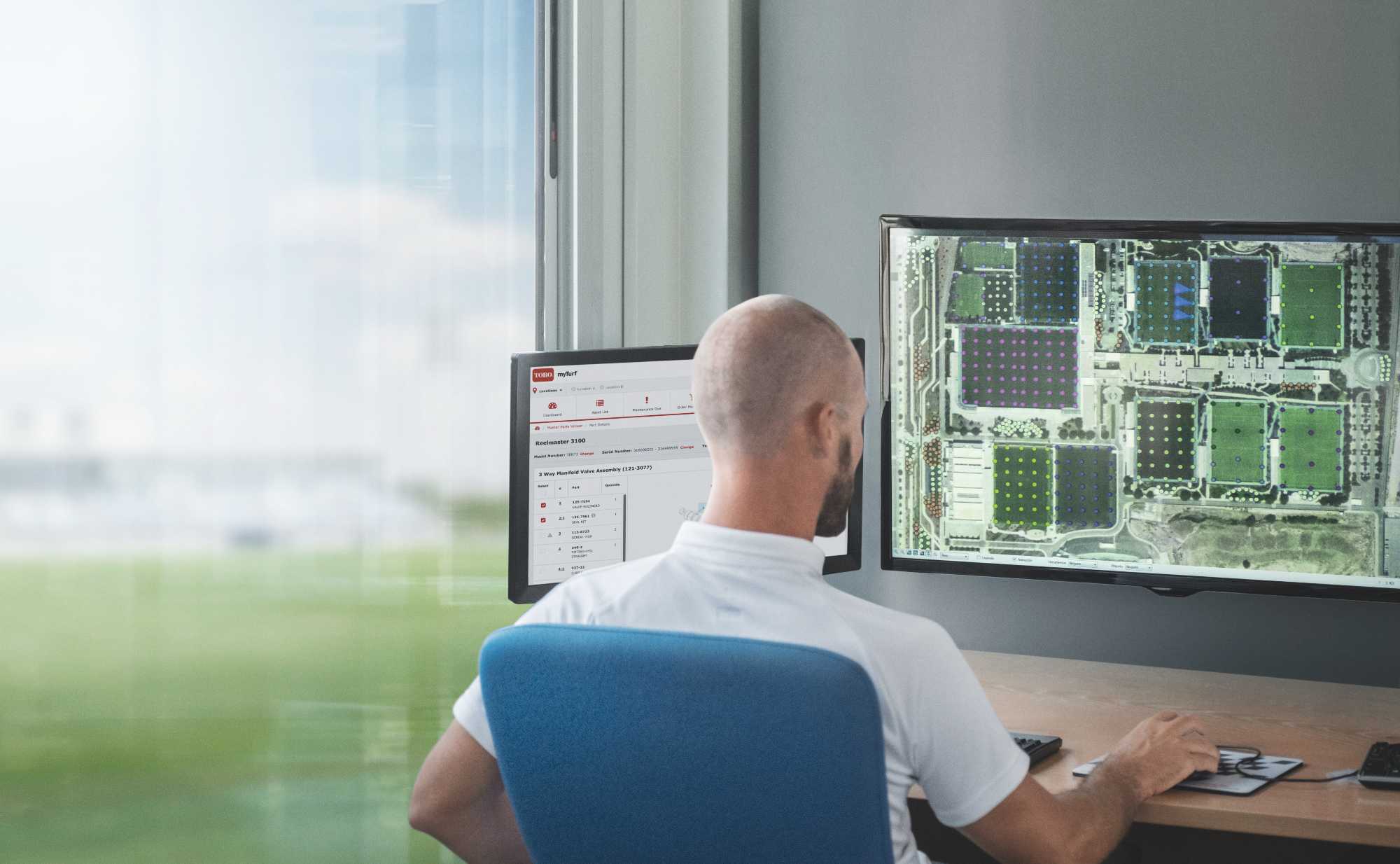

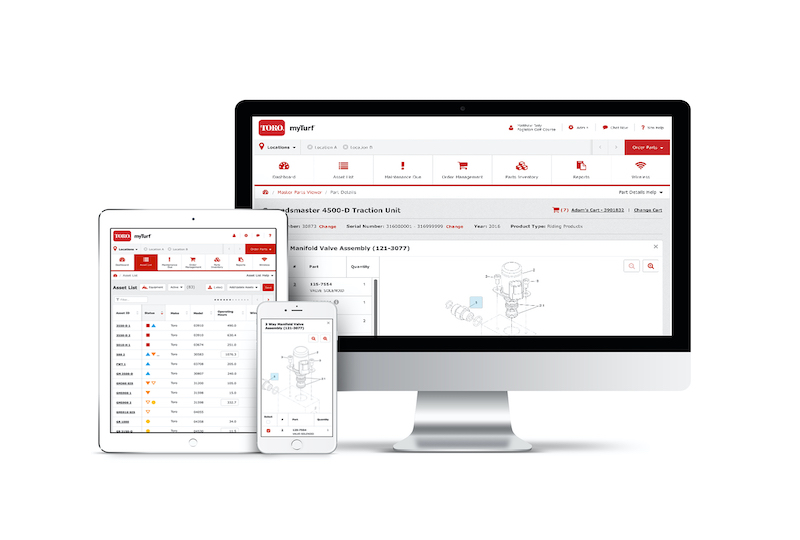

Turfcare machines, regardless of brand, now include high-tech electronic or hydraulic drive systems, similar to those found in some top performance cars. Just as you wouldn’t drive a car that has not been serviced, the same should be said for turfcare machinery.

Cleanliness, regular daily checks and service intervals should take priority when it comes to protecting your organisations most expensive assets. It’s important to follow a machinery maintenance schedule implemented by a trained mechanic, which will in the long term decrease the cost of repairs and lengthy downtime and keep the equipment productivity at maximum.

The benefits of training

In order to stay up to date with advancements in machinery technology and ensure your machinery maintenance skills are able to cope with new developments in the industry, it’s important to seek out and undertake additional training. With the rate at which technology develops, and with health and safety and machinery regulations subject to change, there are many factors which could make undertaking the latest training programmes even more beneficial. That’s why Reesink have added a series of 12 new refresher courses to their training programme for 2020.

A refresher course would be the perfect way to stay up to date with the best techniques and practices when it comes to machinery maintenance, building on pre-existing experience and training with the latest knowledge of the industry. And good quality machinery maintenance is not to be underestimated, particularly when taking one day to complete a refresher course could see your machinery benefit year-round.

This is a view that Peter Todd, Royal Norwich Golf Club’s estates manager strongly agrees with. With 30 years of experience in the industry, Peter knows more than most the benefits of what well-maintained kit can bring, and with Royal Norwich’s new course heading into its first winter it’s something at the forefront of his mind.

“Keeping on top of general maintenance ensures your machines are in the best possible condition. It can be tempting to cut corners when it comes to preventative service work, but breakdowns and downtime are more expensive and well-maintained kit tends to be trouble-free in comparison.

“In order to keep standards high, you have to keep your machinery in top notch condition and paying attention to parts maintenance is your first point of call in order to do that. There is a tendency to push the majority of machinery maintenance into the off season when there are fewer jobs to do around the course and cutting frequency has decreased, and while it does provide the time to do the machine’s ‘MOT’ if you like and a full service and deep clean, you’ll never regret paying attention to your machinery and parts maintenance throughout the year.”

Daily maintenance

With the amount of maintenance that is recommended to be carried out either daily or on a regular basis, it’s no wonder that knowing the ins and outs of maintenance after completing relevant training is so helpful.

Some daily checks are simple and take up little to no time. Checking for fluid leaks and damaged hoses, units can be carried out with a cursory glance and investigated further if required, whereas interlock switches, braking, steering and instrument operation are normally checked the moment the operator drives from the shed. Checking oil levels, air filter and tyre pressures becomes routine and takes little time to do. It is possible with some greens machines that a difference of 1 psi in the tyre pressure will give a 0.25mm mismatch, which is visible to the naked eye.

At the end of a day’s work, it’s also worth taking the time to wash units down with low-pressure water – lubricate to purge any water and top up the diesel tank to minimise any condensation forming in the tank overnight.

While these checks may be simple to make and any adjustments needed quick and easy to implement also, when you start to look at what is needed to ensure the highest quality of cut possible, the maintenance can become more complicated and time consuming.

Ensuring the quality of cut

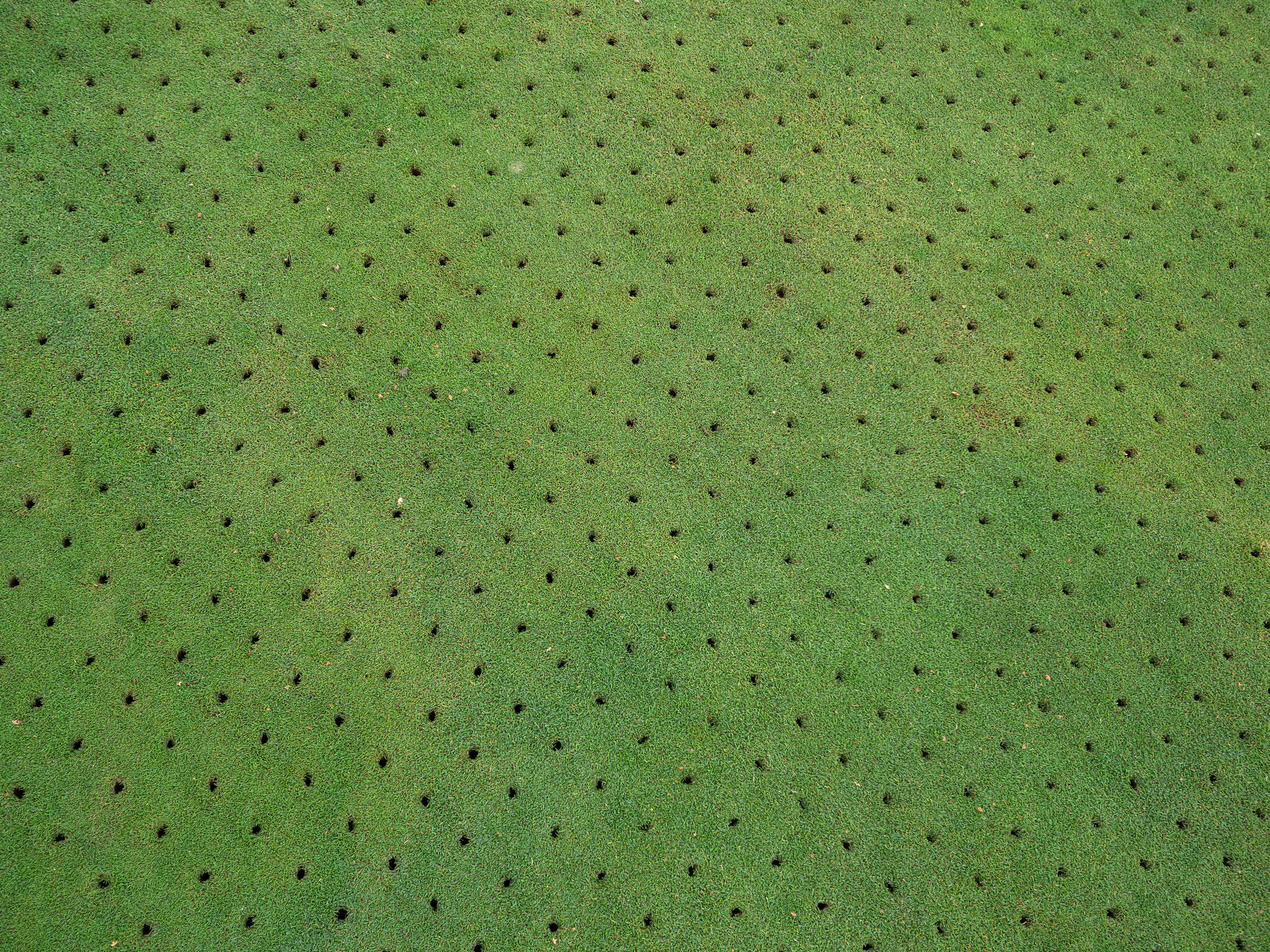

One of the most important daily checks is to verify the unit is on cut. This will reduce the risk of damage to the cylinder, excessive wear on the moving parts, and give a better quality of cut. There are so many variables that can affect quality of cut and it is important to understand all factors involved.

Bedknife to Cylinder adjustment

Both the cylinder and bedknife’s cutting edges need to be straight and sharp, so grind as necessary and back lap little and often. The cylinder should be adjusted to the bedknife so that it pinches paper when placed between the two, and cuts paper when it is passed over the bedknife into the path of the cylinder. This is one of the most effective preventative maintenance practices.

It is also particularly important in the winter season to keep up bedknife maintenance. With wet grass and earthworm castings in the autumn and winter, keeping blades sharp becomes more difficult. When blunt blades can also increase the risk and spread of disease in your turf, there’s an added reason to ensure the proper maintenance of your machinery parts in winter.

Attitude adjustment

‘Attitude’ refers to the bottom of the bedknife and the ground plane under the cutting unit. A large angle is referred to as an aggressive bedknife attitude. The opposite applies to a small angle and in this less aggressive set-up the bedknife can be riding on the turf. This is one of the first places greenkeepers should look when trouble-shooting aftercut appearance issues. Designs in units, such as the DPA unit and the bedbar pivot location, now allow for operators to maintain a virtually-constant aggressiveness as the cylinder wears.

Rollers

Rollers need to be set parallel with the cylinder, using a set-up plate. At the same time roller bearings should be checked for excessive play. Modern components such as the DPA unit have rollers that are parallel with the cylinder throughout and do not require the need to set the rollers in a parallel position.

Height of cut

This should be checked often for your desired finish. As with tyre pressure, errors in setting the height of cut on a greens machine by as little as a 0.25mm mismatch will be visible to the naked eye. With golf courses achieving ever-lower heights of cut on their greens, it is becoming more critical to achieve a consistent standard across grounds by setting heights of cut.

Engine

Particularly in the winter when the cold weather can have an effect on machinery starting systems making it more difficult to get them up and running, it’s a good idea to check the batteries and electrics on a more regular basis. Additionally changing the oil and cleaning blocked air filters will help to save time in the long run.

Adapting to the season

It’s also important to consider the conditions you’re using your machines in, and make changes to ensure they are equipped to deal with those conditions. When the grounds are wet, particularly in the colder season, it’s a good idea to switch to new tyres. Ensuring you have improved grip in unforgiving ground conditions will help make sure productivity remains high and keep your machinery safe.

Training and machinery

Over the last several years, there’s been an increase in operator and mechanic training courses. The introduction of these courses has provided numerous opportunities for dealers, mechanics, greenkeepers and groundsmen in the agricultural, fine turf and groundscare industry.

This structured training has helped contribute to the improvement of safety in the industry, customer care and after sale satisfaction. With the increased knowledge, skill and experience completing training can bring, you can keep your machinery working better for longer, so the advantages of undertaking training – whether a full course or a shorter refresher course – should never be underestimated.

For further information on Reesink’s training call 01480 226800 or browse through the range online here. Booking can be done through the website. To stock up on Toro Parts or for winter machinery maintenance advice, customers can get in touch with their local genuine Toro parts dealer or service centre and online.

November 2019

Reesink UK LTD | 1-3 Station Road, St Neots PE19 1QF | Registered in England

Reesink UK LTD is authorised and regulated by the Financial Conduct Authority.