- CONTACT US

- MOWERS

- VEHICLES

- APPLICATION

- Golf

- AERATORS

- VEHICLES

How to Keep Rollers Rollin'

CONTENTS

FEATURED STORIES

Reesink Turfcare

Reading time: 10 minutes

How to keep your turfcare machinery in top condition

Keeping cylinders and blades sharp and filters clean is an important aspect of turfgrass mowing. Why?

Because it ensures machines run smoothly and keeps grass thick and healthy. Maintaining cutting and power units, therefore, is critical to optimising your mower’s performance, and blades and filters must be looked after as a result.

Yet, despite this, mower blade and filter maintenance is a job that’s often overlooked.

Why it’s important to regularly check, service, and maintain mower blades

When it comes down to it, cutting heads and blades do all the work; they perform the cut. So if they’re not looked after and kept in proper shape, then you can expect poor cutting performance.

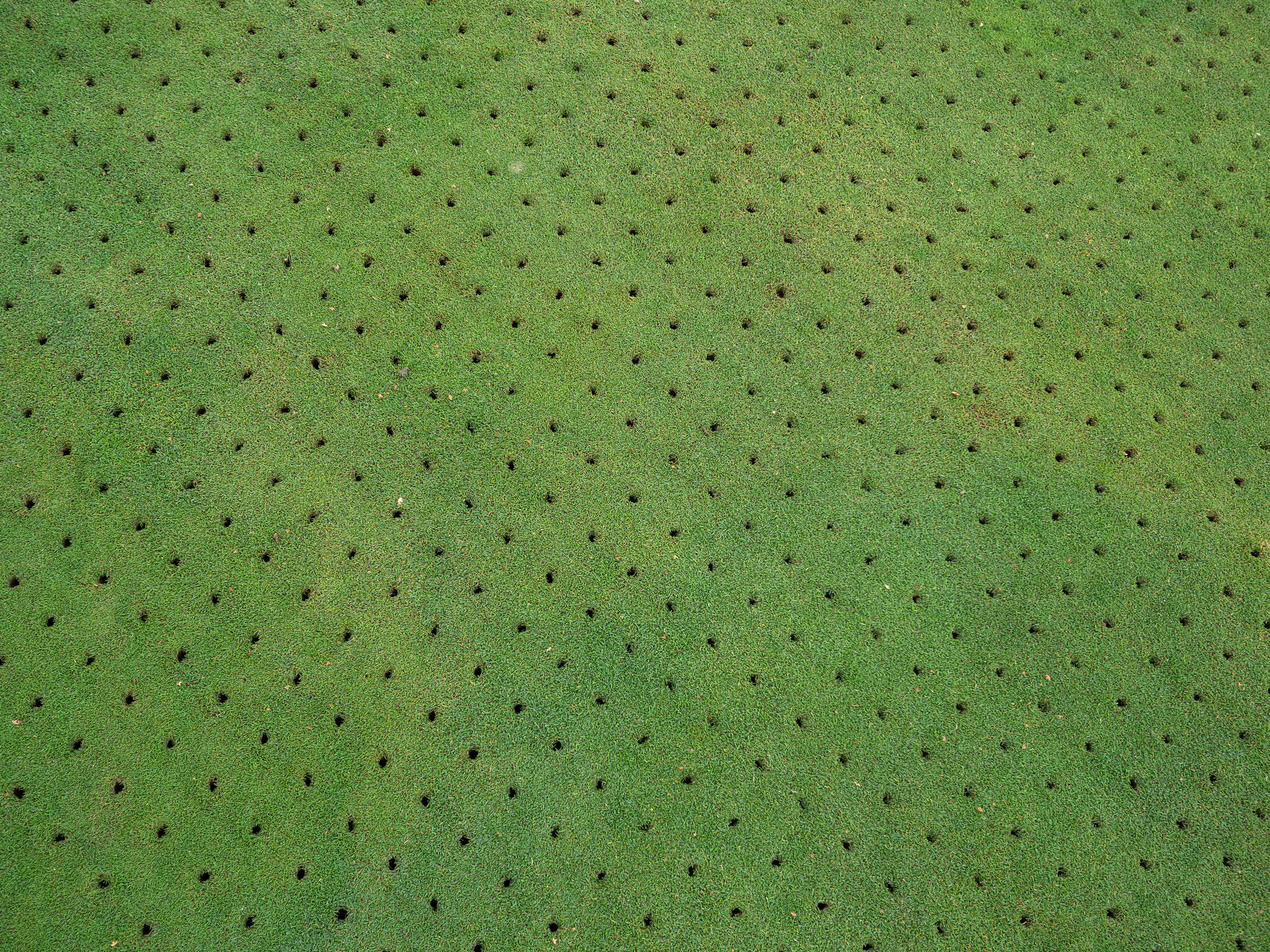

Dull blades and cutting units can cause turf damage and browning

When you forget to sharpen your blades, you can run into several problems. Because dull blades tear turf leaves, instead of cutting them cleanly, disease can enter the leaf, which isn’t good.

You can identify a damaged leaf from the white sheen that will present across the grass. This can lead to tip dieback and, in turn, browning.

Continually mowing with dull cutting units or blades will also cause your turf to thin out. For thicker, greener grass, then, you should always make sure your blades are sharp and ready for the job.

Irregular servicing can lead to a poor after-cut appearance

A poor after-cut appearance is the opposite of what you’d expect from a precision machine. However, it is what you can expect from dull and poorly maintained blades and cutting heads.

When you consider the amount of money you invest in a mower, it’s a real shame to let precision cutting technology go to waste. Don’t let a lack of maintenance be what the members, committee, or board notices, because it’s not the mower’s fault – it’s time to check your blades!

Poorly maintained mowers could damage cylinders and bedknives

This can manifest in various ways from dull cutting edges on your blades to tapered cylinders, where the diameter of the cylinder changes gradually along the length. In both cases, you can expect a poor and uneven finish.

A tapered cylinder can reduce the life of the cylinders as the correction process requires the taper to be ground away, while an incorrect adjustment will mean frequent sharpening and replacing of cylinders and bedknives, which can also prove costly.

Blade maintenance is crucial to extending your mower’s lifespan

If your blades are poorly maintained, then your mower will use more fuel and energy to do the same job, which can put extra load on hydraulics and the electric motor.

Consequently, because the machine’s being taxed more heavily, this could reduce the lifespan of your machine significantly – not to mention adding extra fuelling and running costs to the machine.

How often should you check your mower’s blades?

Toro recommends cutting units should be checked daily for quality and height of cut. You should ask your operators and greens/grounds team to be vigilant; if they feel the machine isn’t cutting properly, or if they feel they might’ve hit something, then encourage them to speak up.

It could save you – and your machine – a lot of trouble in the long run.

How to check your blades… like an expert

The paper test is a simple but effective way to check the cutting edges of your greens mower to see if they’re dull, bent, or nicked.

Perform the paper test to assess blade health on a greens mower

Simply insert a long strip of cutting performance paper (Toro Part No. 125-5610) between the cylinder and the bedknife, so that it’s perpendicular to the bedknife. Then, slowly rotate the cylinder forward; it should cut the paper.

If there’s a problem cutting the paper, then it’s likely your blades need sharpening. The cylinders could have become cone shaped, rounded, or otherwise have nicks or chips.

Three blade maintenance protocols that should be in every course mechanic’s repertoire

Once a problem is diagnosed, you can utilise grinding, adjustment, and backlapping tools to maximise the quality of cut and the mower’s performance.

Grinding tips for a top quality cut

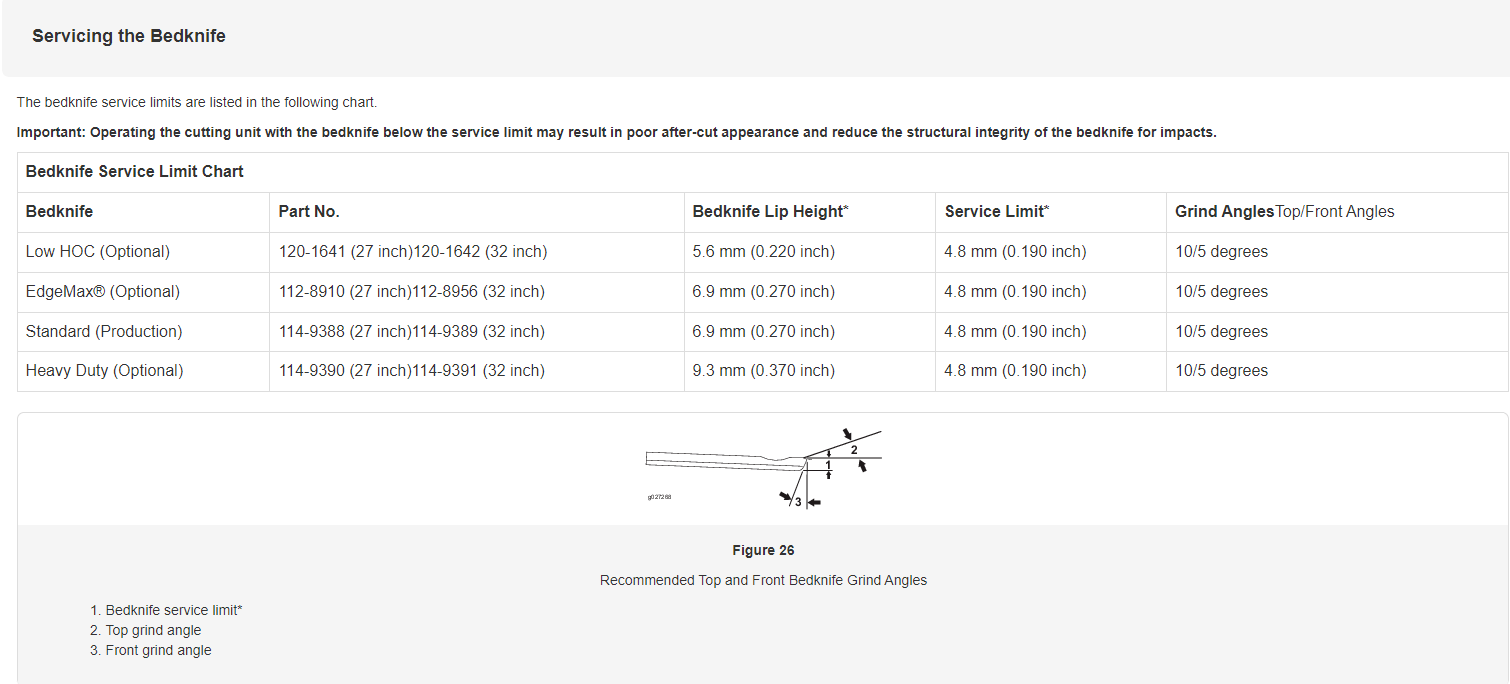

When it comes time for operators to grind cylinders and bedknives in high-performance machines, such as those made by Toro, it’s important to trust the machinery manufacturer’s guidance.

With Toro, for example, you should use recommended grinding angles to maintain a correct quality of cut and enhance the longevity of the cutting edge on your machine.

Depending on operating conditions on a golf course, most machines should be sharpened twice in the cutting season for peak performance.

Don’t underestimate the power of adjustment

It’s critical you maintain proper adjustment on all greens mowers. Indeed, cylinder mowers should be checked after each use to ensure that correct bedknife and/or cylinder alignment are at manufacturer specifications. Doing so ensures your mower’s operating as it was designed to!

Backlapping is key to keeping a sharp edge

Backlapping is a lawnmower maintenance process used to keep a sharp edge on a cutting cylinder. It involves applying a specialised grinding compound, typically a lapping paste, to cylinder blades, and rotating them backwards.

On modern machinery, backlapping can be performed mechanically, rotating the cylinder backwards at a set speed to remove nicks, burrs, or imperfections on the blades’ cutting edges, enhancing their sharpness and improving their quality of cut.

When is it time to replace your blades?

If there’s not enough material left to give a lasting cutting edge after being surface ground back to the recommended angles, then it’s time to replace your bedknives.

You can typically find wear limits for bedknives on the manufacturer’s website. All cylinders will have a specified service limit diameter, and once reached, typically as a result of wear and regrinding, they will no longer gather the turf leaf correctly prior to it reaching the shear point.

Ultimately, this will lead to an uneven cut. If the service limiter diameter has been reached, operators will need to look into replacing their blades.

For Toro users, cylinder service limits and bedknife grinding angles can be found via this handy chart.

Filter health is essential for overall mower performance

High performance machines will have a number of filters, including air, oil, fuel, and hydraulic. Each serves a different function within the machine.

As a whole, filters prevent contaminants from reaching the machine’s engine and other vital systems. Failing to maintain them can reduce engine performance, decrease fuel efficiency, increase emissions, and, in a worst case scenario, result in engine damage and a shorter lifespan for your machine.

Did you know that neglecting to perform proper filter maintenance with Toro machinery can also make your warranty become void? So regular servicing is crucial!

The importance of keeping on top of filter maintenance

When it comes to the different maintenance programmes needed for different filter types, and how to ensure your filters continue to perform to their maximum potential, there are several steps operators should take.

Understanding air filter maintenance

When an air filter gets too dirty, it will get clogged and the engine won’t be able to suck enough air into the combustion chamber. When this happens, engines use more fuel and less air, resulting in poorer performance and a drop in fuel efficiency.

Air filters in greens mowers should be checked and cleaned as part of a daily check protocol. Every 200 hours, though, they should be fully serviced.

Understanding oil filter maintenance

Over time dirt and other particles in dirty oil can clog up oil filters and reduce its flow to critical parts of your mower’s engine. This can lead to increased friction and heat build-up, which could ultimately mean costly repairs or even complete engine failure.

Oil filters should be changed along with the oil after the first 50 hours, and then every 150 hours after that.

Understanding hydraulic filter maintenance

A clogged hydraulic filter releases contaminants into your hydraulic system, which isn’t good. But did you know it can also result in failures of other hydraulic components down the line?

These future faults can wreak havoc and result in extensive downtime, which is why it’s important to change your machine’s hydraulic filters on a regular basis. Using Toro’s PX Extended Life Hydraulic Fluid, the hydraulic filter can be replaced every 2000 hours.

Understanding fuel filter maintenance

With fuel filters, a lack of maintenance can lead to worn or damaged fuel system components, a poor running engine, downtime, and very costly repairs.

Water needs draining from the diesel filter separator daily, and every 400 hours, operators should replace the fuel filter canister.

How to tell when a filter needs immediate attention

There are a number of signs you can look for that might signal a filter needs immediate attention.

Recognising evidence of overheating, reduced fuel economy and horsepower, as well as hydraulic component failure, could mean a filter needs immediate attention.

For air filters, most Toro machines will have a filter indicator on the side of the filter casing. When the engine is running the indicator will turn red if the filter is blocked, which means you will need to swap it out for a new filter.

Always use genuine blade and filters to get the most out of your mower

The quality of parts can have a huge impact on the running of a mower, especially a high-performance one made by Toro.

To get the most out of your blades and filters, use genuine Toro filters and oil as using non-genuine parts can have a detrimental effect on the machine and, in some cases, even result in engine failure.

Generic air filters can allow up to 10 times more dirt to pass into the engine than Toro ones, which are manufactured to meet or exceed engine and application requirements.

Get complete peace of mind with ReeAssure maintenance plans

Using the above advice, operators should be able to complete the day-to-day maintenance on their machines themselves, however our ReeAssure scheme gives an extra level of support.

With bronze, silver, and gold plans, there’s a scheme suitable for every club. Each plan includes the manufacturer's routine maintenance and scheduled servicing, removing the unknowns and making maintenance planning easy.

The gold plan goes one step further to include unlimited visits, all breakdown and call-out costs, Toro genuine parts, and all electrical components.

It’s the perfect option for those wanting to keep their machinery in optimum condition year-round, as well as extending machine warranties from two years to five.

Reesink UK LTD | 1-3 Station Road, St Neots PE19 1QF | Registered in England

Reesink UK LTD is authorised and regulated by the Financial Conduct Authority.